What are the types of industrial pipes and their application?

- Steel Pipes

- Copper Pipes

- PVC Pipes

- HDPE Pipes

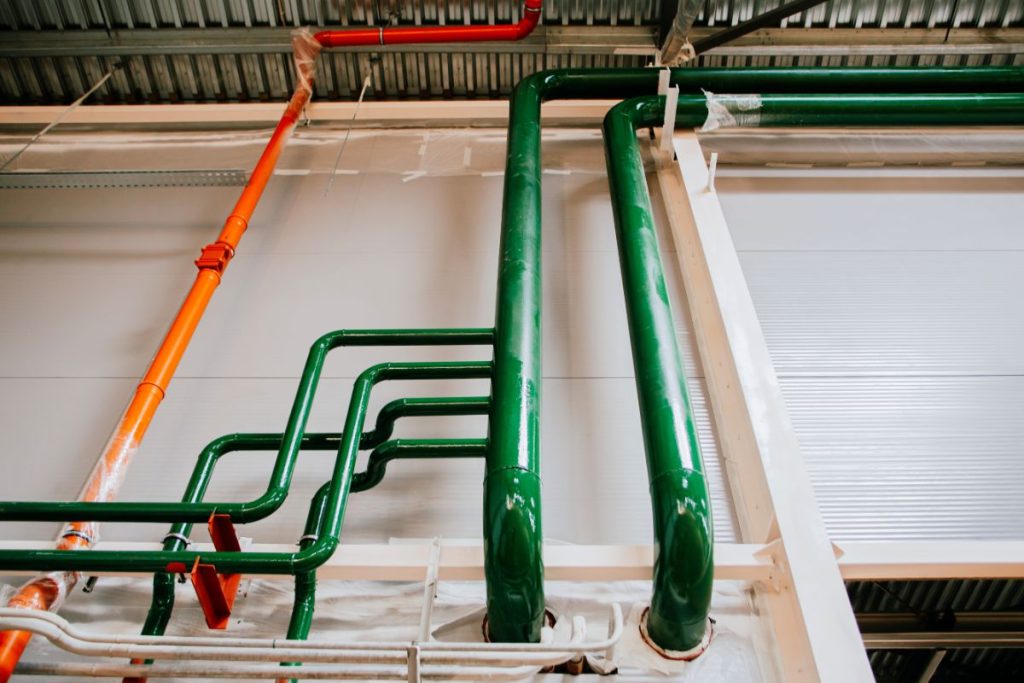

Industrial pipes are an essential component of many industries, from transporting oil and gas to conveying water and other liquids. There are various types of industrial pipe available, each with unique properties and applications.

In this article, you will find the differences between these types of pipes, which are crucial to selecting the right one for your project.

Steel Pipes

Steel pipes are a popular choice for industrial applications due to their durability, strength, and resistance to high pressure. They are commonly used in the oil and gas industry for transporting fluids and gases over long distances. Steel pipes are available in different grades, depending on the application requirements. These pipes are also commonly used in structural applications, such as in the construction of buildings and bridges.

One of the most common applications of steel pipes is in the construction industry. They are used for structural purposes such as framing, scaffolding, and the construction of bridges and buildings.

Steel pipes are also used in the transportation of liquids and gases, including water, oil, and natural gas. In the oil and gas industry, steel pipes are used for drilling and well operations, as well as for the transportation of oil and gas through pipelines.

Steel pipes are also commonly used in the manufacturing of industrial equipment and machinery. They are used in the production of conveyor systems, heat exchangers, and boilers. Additionally, steel pipes are used in the manufacturing of automotive parts, such as exhaust systems and suspension components.

Copper Pipes

Copper pipes are known for their excellent heat conductivity and corrosion resistance, making them suitable for various industrial applications. They are commonly used in plumbing, air conditioning, and refrigeration systems due to their ability to efficiently transfer heat. Copper pipes are also resistant to corrosion and can last for many years, making them a cost-effective option for industrial applications.

In addition to their heat conductivity and corrosion resistance, copper pipes are also easy to install and maintain. They are lightweight and flexible, which allows for easy bending and fitting into tight spaces. This versatility makes them suitable for various applications, from residential plumbing systems to large-scale industrial HVAC systems.

In addition to their excellent thermal and electrical conductivity, copper pipes offer another significant advantage: recyclability. Copper is one of the few metals that can be recycled indefinitely without losing its properties, making it an environmentally friendly choice for piping applications.

Copper pipes are easy to recycle since they can be easily melted down and reused in the production of new copper products. Recycling copper also has significant energy savings as it takes up to 85% less energy to recycle copper than to extract new copper from the ground.

PVC Pipes

PVC (polyvinyl chloride) pipes are a type of plastic pipe that is widely used in industrial applications. They are valued for their durability, low cost, and corrosion resistance. PVC pipes are lightweight and easy to install, which makes them ideal for use in drainage, irrigation, and wastewater treatment systems.

One of the most significant advantages of PVC pipes is their ability to resist corrosion and chemicals, making them ideal for use in harsh environments. They are also resistant to UV radiation, making them an excellent choice for outdoor applications. Moreover, PVC pipes are easy to maintain and require minimal maintenance throughout their lifespan.

Another key advantage of PVC pipes is their affordability, making them a popular choice for industrial applications. They are relatively inexpensive compared to other materials such as steel or copper and can be manufactured in a range of sizes and thicknesses to meet specific application requirements.

HDPE Pipes

HDPE (high-density polyethylene) pipes are a type of plastic pipe that is commonly used in industrial applications due to their high strength, durability, and resistance to corrosion. HDPE pipes are made of a thermoplastic material that can be melted and reshaped multiple times without losing its strength, which makes it ideal for applications where flexibility and durability are key factors.

One of the main advantages of HDPE pipes is their resistance to corrosion and chemicals, which makes them ideal for use in harsh environments such as chemical processing plants and sewage treatment facilities. HDPE pipes are also resistant to UV radiation and are suitable for outdoor applications.

Additionally, HDPE pipes are lightweight, easy to install, and require minimal maintenance, which makes them an excellent choice for a wide range of industrial applications. They are also cost-effective compared to other materials such as steel or copper, making them a popular choice for many industries.

Key Takeaway

Choosing the right industrial pipe is crucial for project success. Each type of pipe has unique advantages and applications. Factors such as strength, durability, corrosion resistance, and cost must be considered to ensure that you are using the right material.

If you are looking for a Philippine supplier of steel pipes, one of the most durable and versatile types of industrial pipes, you can check us out at Supreme Pipe Corp. Our experts can provide appropriate materials for your industrial needs.