Download Our Catalog For FREE

Our Process

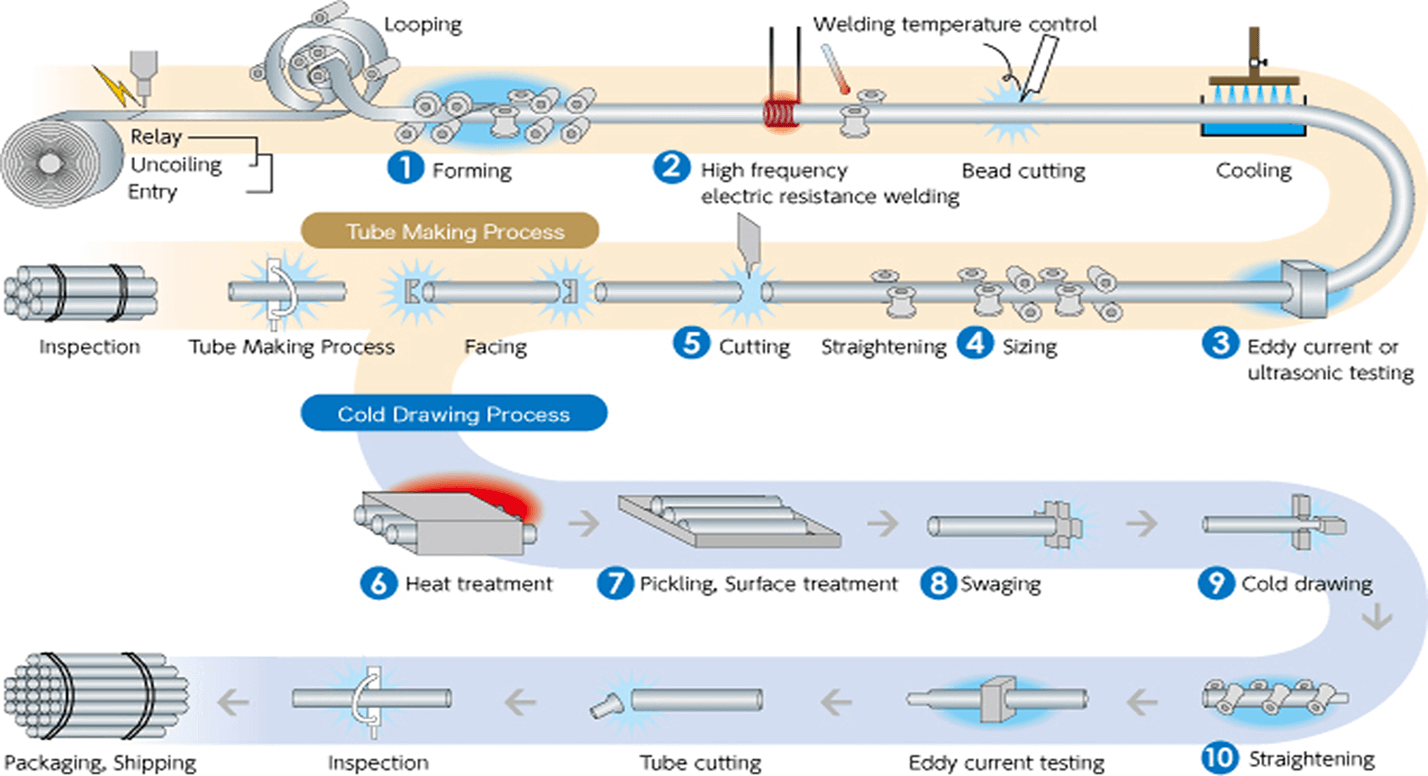

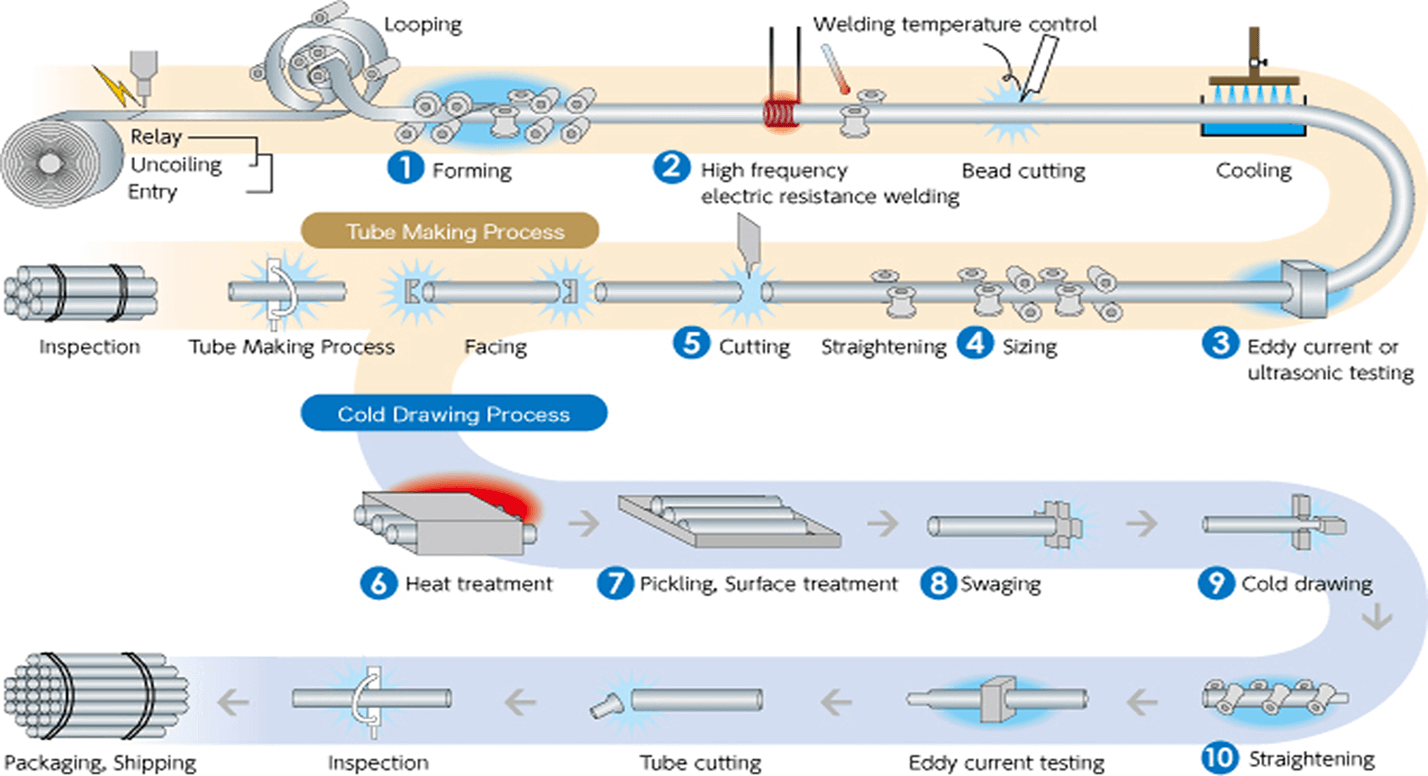

ERW PRODUCTION

GALVANIZING (Blowing System)

This blowing system is an adapted Japanese technology and one of the newest methods of galvanization. The steps are as follows:

Metal Preparation

The pipes go through the process of pickling, degreasing, and fluxing in preparation for the dipping process.

Pre-dipping Phase

Dipping

The pipes are immersed into a tank of molten zinc.

Auto Pick-up Device

Also called as the post-dipping procedure.

Air Wipe System

This process ensures the zinc coating to be evenly spread on each pipes’ surfaces.

Steam Blowing System

This system blows our internal zinc excesses.

ERW PRODUCTION

GALVANIZING (Blowing System)

This blowing system is an adapted Japanese technology and one of the newest methods of galvanization. The steps are as follows:

Metal Preparation

The pipes go through the process of pickling, degreasing, and fluxing in preparation for the dipping process.

Pre-dipping Phase

Dipping

The pipes are immersed into a tank of molten zinc.

Auto Pick-up Device

Also called as the post-dipping procedure.

Air Wipe System

This process ensures the zinc coating to be evenly spread on each pipes’ surfaces.

Steam Blowing System

This system blows our internal zinc excesses.

Application

INDUSTRIAL

Agriculture & Irrigation

Automobile Industry

Bearing Casing

Collieries for extraction of water

Thermal power and Transport

Communication Tower

High Temperature and Pressure

Manufacturing Processes & storage

Pumps & Cable Protection

(Electrical & Telecommunications)

Shipping Industry

Steel Palettes

ARCHITECTURAL

Aesthetic & design function materials

Carving and Sculpture

Dome and other aesthetic construction

LIQUID & GAS

Exhaust Tubing

Petroluem line, Oil Refinery Equipment

Residential and Office water lines

SANITARY

Sewage & Excretory Lines

STRUCTURAL

APPLICATIONS

Concrete Piling Casing, Pipe Casing

Scaffholding

Steel Pole, Pole Signage, Fencing, Handrails

SAFETY & RECREATION

Fire Alarm, Springkles System

Golf Course & other landscape

Underground

Sprinkler pipes

Playground Equipment

INDUSTRIAL

Agriculture & Irrigation

Automobile Industry

Bearing Casing

Collieries for extraction of water

Thermal power and Transport

Communication Tower

High Temperature and Pressure

Manufacturing Processes & storage

Pumps & Cable Protection

(Electrical & Telecommunications)

Shipping Industry

Steel Palettes

ARCHITECTURAL

Aesthetic & design function materials

Carving and Sculpture

Dome and other aesthetic construction

LIQUID & GAS

Exhaust Tubing

Petroluem line, Oil Refinery Equipment

Residential and Office water lines

SANITARY

Sewage & Excretory Lines

STRUCTURAL

APPLICATIONS

Concrete Piling Casing, Pipe Casing

Scaffholding

Steel Pole, Pole Signage, Fencing, Handrails

SAFETY & RECREATION

Fire Alarm, Springkles System

Golf Course & other landscape

Underground

Sprinkler pipes

Playground Equipment

Markings

To distinguish genuine Supreme, Superior, and Tri-r pipes, see below markings for authenticity.