Why Construction Project Managers Choose Galvanized Iron Pipes for Long-term Durability

Why do construction project managers choose galvanized iron pipes for long-term durability?

- Corrosion resistance

- Extended lifespan

- Strength and durability

- Versatility and fire safety

- Cost-effectiveness and maintenance

Overview

- Galvanized iron (GI) pipes offer superior corrosion resistance, protecting the steel core with a durable zinc layer and ensuring long-term structural integrity.

- Their strength, extended lifespan, and versatility make them ideal for building frameworks, water supply lines, fire sprinkler networks, HVAC systems, and irrigation, supporting reliable, low-maintenance projects.

When managing a construction project, you need materials that can withstand corrosion, structural wear, and daily operational stress. Choosing the wrong pipes can compromise timelines, safety, and long-term performance.

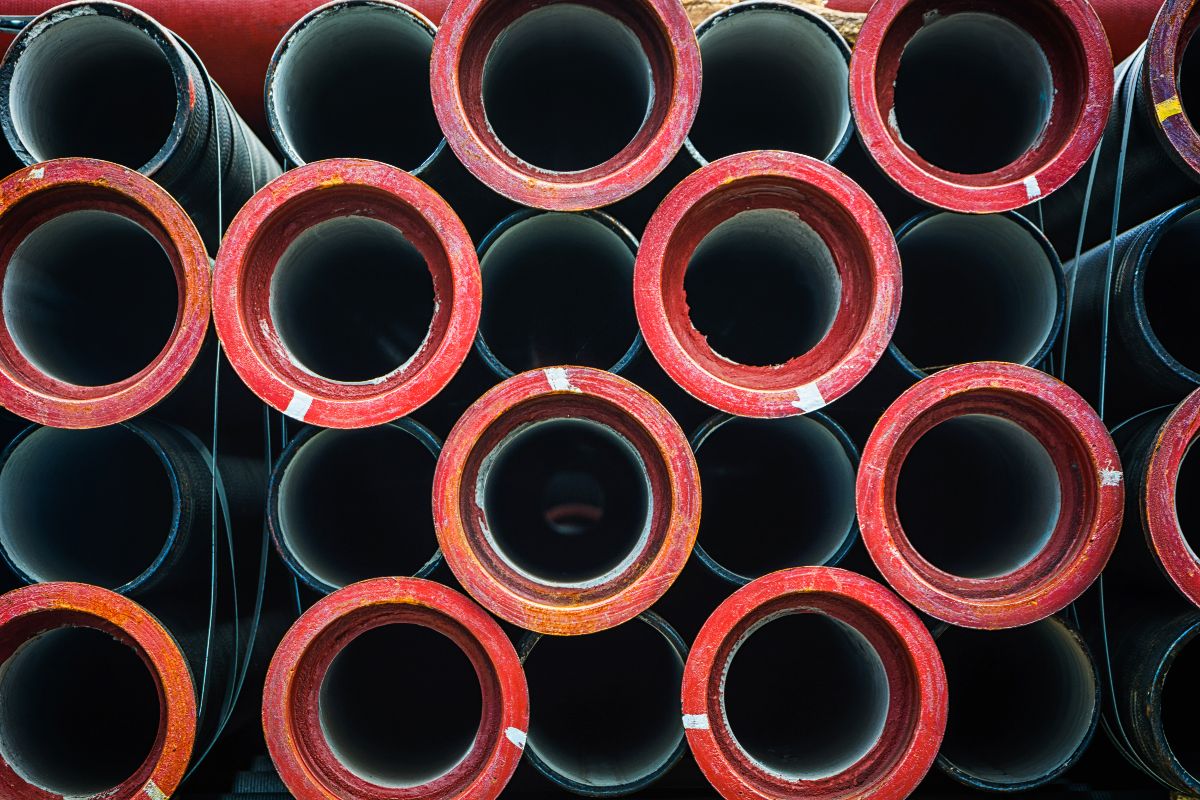

Galvanized iron (GI) pipes are built for durability. Coated with a protective zinc layer, these steel pipes resist rust and environmental wear, giving you confidence that your piping system will remain reliable over the years.

In this article, we’ll explore how galvanized iron pipes’ long-term durability benefits your projects, helping you protect investments, reduce maintenance, and understand why GI pipes are a preferred choice for long-lasting construction systems.

Corrosion Resistance

A major reason project managers choose GI pipes is their superior corrosion resistance. The galvanization process coats steel pipes with a zinc layer, forming a barrier that prevents moisture and chemicals from reaching the steel. This slows rusting, keeping the steel core intact.

Unlike black iron or uncoated steel, GI pipes maintain integrity in wet or chemically aggressive environments. This makes them reliable for pipelines exposed to harsh conditions while reducing the risk of premature failure and project disruptions.

Extended Lifespan

Galvanized iron pipes offer an impressively long service life, typically lasting 40 to 100 years depending on conditions. The zinc layer corrodes first, protecting the steel core from damage, cracking, and wear.

This reduces the need for frequent replacements, minimizing interruptions and maintenance schedules.

By maintaining structural integrity over decades, GI pipes support cost-effective, hassle-free project management and long-term investment reliability.

Strength and Durability

GI pipes retain the natural strength of steel while benefiting from the toughness of the zinc coating. This ensures they withstand physical impacts, pressure fluctuations, and everyday wear without compromising structure.

Their robustness makes them ideal for demanding applications, including building frameworks, water supply networks, and infrastructure projects.

By choosing GI pipes, you gain both strength and reliability, supporting long-lasting performance under challenging conditions.

Versatility and Fire Safety

GI pipes are highly versatile and used in water supply lines, fire sprinkler systems, HVAC networks, and irrigation setups. The steel core provides load-bearing capacity, while the zinc coating adds heat and fire resistance.

Compared to plastic or non-metallic pipes, GI pipes enhance fire safety, protecting structures and occupants.

This combination ensures safety, operational efficiency, and adaptability for multiple construction needs.

Cost-effectiveness and Maintenance

Although GI pipes may have a higher upfront cost than uncoated steel pipes, durability and minimal maintenance make them cost-effective over time. Frequent repairs and replacements are avoided, lowering lifecycle costs.

Lower maintenance means fewer project delays and reduced labor, optimizing your construction budget.

GI pipes deliver a high-performing, long-lasting system that protects your investment while reducing upkeep demands.

Common Applications of Galvanized Iron Pipes

Galvanized iron pipes are highly versatile, offering strength, corrosion resistance, and durability for multiple construction and infrastructure applications across the Philippines. By choosing them, you ensure reliable performance for your projects, whether it’s residential, commercial, or government work.

Building Frameworks

GI pipes are strong and reliable, making them ideal if you need structural supports that last. The steel core provides excellent load-bearing capacity, while the zinc coating protects against corrosion from humid climates and seasonal rains.

Using these pipes ensures long-term stability and low-maintenance frameworks, perfect for construction projects in the Philippines’ tropical environment.

Water Supply Lines

Corrosion resistance keeps water flowing safely and efficiently through your systems. The zinc layer prevents rust and contamination, so you can be confident that water delivery remains clean and consistent for both urban and rural communities.

GI pipes’ durability lowers the risk of leaks and failures, helping you maintain reliable water flow even during seasonal rains or fluctuating pressure.

By choosing GI pipes for your water supply lines, you minimize interruptions and ensure your system performs as expected under local conditions.

Fire Sprinkler Networks and HVAC Systems

GI pipes are ideal if you want reliable fire protection and climate control systems in high-rise or commercial buildings. Their strength and corrosion resistance keep your systems operational during emergencies and daily use, even in humid environments.

Using galvanized pipes in your sprinkler and HVAC networks helps protect both occupants and equipment while ensuring compliance with local fire safety codes.

By installing them, you get a system that combines durability, protection, and minimal maintenance, supporting long-term reliability in your critical infrastructure.

Irrigation Systems

Resistant to rust and environmental exposure, GI pipes perform well for your outdoor and agricultural water delivery systems. Their durability ensures consistent flow even under intense rainfall or humid conditions.

Withstanding UV, moisture, and abrasion, these pipes let you maintain efficient irrigation runs while reducing the need for frequent repairs.

For your construction and agricultural projects, this means GI pipes give you reliable irrigation systems that require minimal upkeep and support sustainable water management.

Find Reliable Galvanized Iron Pipes at Supreme Steel Pipe Corp.

We provide high-quality galvanized iron pipes made through precise galvanization processes, ensuring a uniform zinc coating and superior corrosion resistance. With our GI pipes, you can trust that your projects benefit from materials built to withstand the harshest conditions and deliver long-term durability.

We combine decades of industry experience with strict quality standards, giving you reliable piping solutions that reduce maintenance needs and protect your construction investments.

By choosing our GI pipes, you gain peace of mind knowing your systems are supported by a supplier committed to excellence and consistency throughout every phase of your project.

Key Takeaway

By understanding how galvanized iron pipe’s long-term durability makes it a hit for construction project managers, you can make informed material choices that protect your investments, reduce maintenance costs, and ensure reliable, long-lasting performance across your construction projects.

Ensure long-lasting performance on your projects with galvanized iron pipes. We provide high-quality pipes that withstand corrosion and deliver reliable results for construction managers. Contact us today to learn more and secure the right materials for your project.