7 Advantages of Using Steel Pipes Over PVC Pipes

What are the advantages of using steel pipes over PVC pipes?

- Strength

- Durability

- Heat resistance

- Sizing

- Application

- Cost

- Versatility

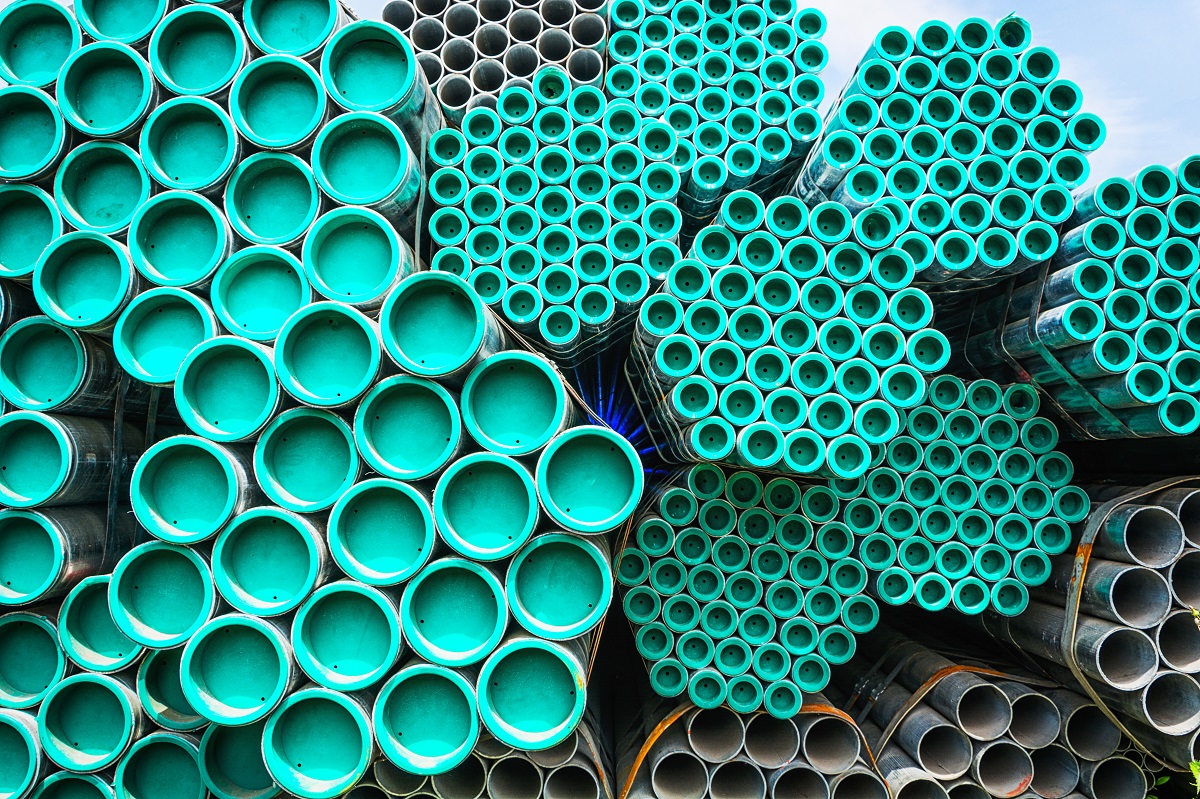

Buildings rely on their piping matrix to keep everything about the structure in order. These structural materials are responsible for plumbing or HVAC systems that help regulate temperature, as well as, facilitate fluid conveyance in a space. In choosing between steel pipes vs PVC pipes, there should be an understanding of the qualities of the steel and plastic material. While each of these pipe classifications has its advantages, the properties of steel have deemed it more suitable for piping applications. Continue reading to learn more.

Strength

The strength factor is important when it comes to choosing pipes. This not only determines how long the pipe can last but also its susceptibility to extreme conditions. Due to the material, steel pipes are generally considered to be stronger compared to PVC pipes.

With stronger pipes, only minimal maintenance work is required to keep the pipe in good working order. Heat treatment methods in the post-processing of steel pipes — particularly cold-working — alter the material’s grain structuring, thus giving it a higher tensile strength rating. Leakages, pitting corrosion, and burst pipes are a far less common occurrence across steel pipes than PVC pipes.

Durability

In line with the strength of steel pipes, they’re also more durable. The most common piping systems for buildings and/or residential spaces nowadays are installed below the ground. These metal products need to be able to support other above-ground structures — it’s important that they’re durable enough to do so.

Instead of breaking, steel is able to bend and still retain its shape despite vibrations or pressure. PVC pipes, on the other hand, may become deformed over time because they are not able to support the pressures and vibrations they’re subjected to. Building owners would benefit from steel pipes better because they don’t have to worry about having to fix piping problems such as clogs and leaks.

Heat resistance

Active steel pipes have a higher heat resistance rating compared to PVC pipes. As such, it shouldn’t come as a surprise that these types of pipes can be used for other purposes, such as for petrochemical works.

Petrochemical pipes are constantly withstanding high pressures and high heat due to the extremity of the operations. For this reason alone, steel pipes make a good choice because they can resist the high heat without breaking. Meanwhile, PVC pipes are not a suitable choice in the petrochemical industry because this can diminish their usefulness. They lose their usability when subjected to temperatures beyond 60 degrees Celsius.

Sizing

Manufacturers are limited when it comes to producing different sizes and capacities of PVC pipes. Contractors and builders may have a problem when it comes to working with PVC pipes because of this fact — they’ll likely experience constraints.

For example, contractors may need to purchase more quantities of the PVC in order to simply accommodate piping work. Unlike in PVC pipe manufacturing, steel manufacturing is far less constrained and more versatile. Manufacturers can come up with a range of diameters and lengths for steel pipes, depending on the purpose.

Application

As mentioned before, there is also a wide range of uses for steel pipes. They’re not only found in HVAC, piping, and petrochemical systems — instead, they may also be used in structural works that are both functional and decorative.

Steel pipes can also be utilized in constructing piling. Piling is usually done in cases wherein the material of the soil in building foundations is not strong enough to support an entire structure above it. The addition of steel pipes serves as a reinforcement to the soil, thus providing a more stable structural support.

You wouldn’t find the same situation regarding PVC pipes. While they may be a flexible option for plumbing or electrical wiring housing, they’re not really ideal in impact and load-bearing situations.

Cost

PVC pipes are more expensive to manufacture than steel pipes, especially when they come pre-cut by the manufacturer. Due to the wide popularity of steel pipes and the manufacturing processes that take place, they’re far more affordable and a more cost-effective option for buildings and other types of structure.

As you may have already learned, PVC pipes don’t necessarily have a good strength rating. When they’re used in less-than-ideal situations, they need to be frequently uninstalled, taken apart, and replaced — this can be costly for building owners. Alternatively, steel pipes don’t exhibit the same negative qualities. They can last for as long as a century even under minimal maintenance.

Versatility

Finally, steel pipes are far easier to install and layout compared to PVC pipes. The latter can be bulky at times, which makes the installation difficult. The quality of PVC pipes might not really hold up, especially in cases wherein they need to undergo further fabrication or refurbishment.

Steel pipes can be indefinitely worked around and heated without losing their quality. If there is any need for post-processing, the material can easily accommodate the activity with ease. They’re also far less bulky to work with, giving pipefitters an easier time when fitting the pipe with other existing systems.

Key Takeaway

Between steel pipes vs PVC pipes, steel is the better choice. They’re stronger, more durable, affordable, and lower cost compared to PVC pipes. If you’re choosing between these two materials, keep in mind the environmental conditions that they have to be subject to. For plumbing, petrochemical, and structural works, it’s definitely more ideal to go with steel.