The Role of Galvanized Steel in Sustainable Construction Practices

Overview

- Galvanized steel is emerging as a cornerstone of sustainable construction in the Philippines due to its durability, low maintenance, recyclability, and energy-efficient production.

- By leveraging these properties, builders can extend the lifespan of structures, reduce resource consumption, and minimize environmental impact.

- Coupled with responsible sourcing, thoughtful design, precise installation, and eco-friendly maintenance, galvanized steel supports a circular economy and enables projects that are both resilient and environmentally responsible.

Rapid urbanization in the Philippines has brought both opportunities and challenges, including high energy consumption, material waste, and short-lived infrastructure. Addressing these challenges requires sustainable construction practices that prioritize durability, efficiency, and recyclability.

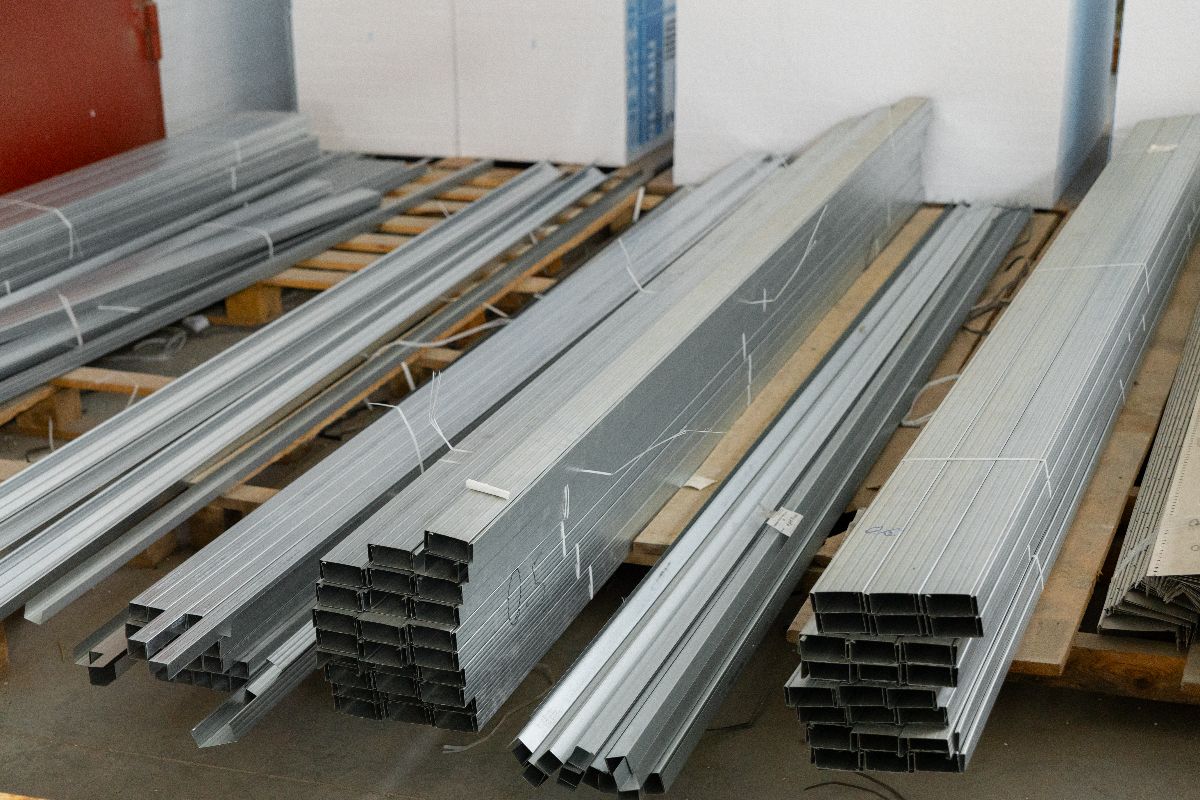

One material rising to meet these demands is galvanized steel, widely used in construction for structural frameworks, roofing, piping, and fencing due to its strength and corrosion resistance.

By incorporating galvanized steel in sustainable construction practices, builders can create structures that are not only robust and reliable but also environmentally responsible, reducing resource consumption and minimizing waste over the life of the building.

How Galvanized Steel Promotes Sustainability

Its inherent properties directly reduce environmental impact, minimize waste, and extend the lifespan of structures.

The following sections explore these key properties, showing exactly how each contributes to more sustainable construction:

Durability and Longevity

The zinc coating forms an effective barrier that prevents the underlying steel from rusting, even in the Philippines’ humid, corrosive, and challenging weather.

This protection allows components, like structural frameworks and the piping offered by Supreme Steel Pipe Corp., to remain functional for 40 years or more without significant degradation.

By choosing a product designed for such a long service life, builders drastically reduce the demand for new material manufacturing and transportation over the structure’s lifetime.

Low Maintenance Requirements

Unlike other metals or untreated steel that demand regular painting or sealing to fight corrosion, the zinc coating is self-sustaining. This eliminates the need for repeated applications of paints, chemicals, and coatings—many of which can contain harmful Volatile Organic Compounds (VOCs).

By reducing the reliance on chemical treatments and frequent maintenance, galvanized steel helps lower environmental pollution. It also cuts long-term maintenance costs, making it both an eco-friendly and cost-effective choice for construction projects.

Energy Efficiency in Production

While steel production is energy-intensive, the galvanization process itself is efficient. More importantly, the lifecycle energy balance is highly favorable.

The initial energy used to create and galvanize the steel is quickly offset by the decades of low-maintenance service it provides.

Modern steel production further boosts efficiency by utilizing electric arc furnaces, which heavily rely on recycled scrap metal, minimizing the energy and resources needed compared to using virgin ores.

Recyclability and Reuse

Steel is one of the most recycled materials globally, and galvanized steel is fully recyclable and reusable. When a structure is finally decommissioned, the steel can be recovered and processed without losing its inherent properties.

The zinc coating is easily separated or integrated back into the recycling stream. This capability supports a circular economy, cutting the demand for virgin resources and drastically reducing the volume of construction and demolition (C&D) waste sent to landfills.

Reduced Resource Consumption

The collective impact of the material’s long service life, minimal maintenance, and complete recyclability leads to a substantial reduction in overall resource consumption.

Longer product lifespan delays the need for new material extraction, while efficient recycling ensures that when a component is replaced, its material value is conserved.

This comprehensive approach to resource management is vital for sustainable growth in rapidly developing regions like the Philippines.

Sustainable Practices when Using Galvanized Steel

While galvanized steel provides a strong foundation for sustainability, human decisions and practices determine how effectively these benefits are realized.

The sections below highlight practical strategies to maximize the sustainability potential of galvanized steel in every stage of construction:

Responsible Sourcing

Builders must partner with manufacturers and suppliers who adhere to ethical labor standards and use environmentally sound manufacturing processes.

When purchasing, clients should choose companies like Supreme Steel Pipe Corp. that are committed to quality and transparency, ensuring the environmental gains of the material are not compromised by unsustainable practices upstream.

Designing for Longevity

Sustainable design starts with planning for the long term. By anticipating structural loads, environmental exposure, and potential future modifications, architects and engineers can ensure that galvanized steel components are utilized in ways that extend their lifespan and minimize waste.

Efficient Fabrication and Installation

This involves using precise cutting and joining techniques, ensuring a “measure twice, cut once” philosophy, minimizing material waste, and reducing the need for energy-intensive rework.

For galvanized piping systems, precision installation minimizes potential leaks, which is a crucial element of water conservation mandated by the Philippine Green Building Code.

End-of-life Recycling

Planning for deconstruction and recycling ensures that galvanized steel does not end up in landfills. Proper dismantling techniques and recycling programs allow both the steel and zinc coating to be reused, closing the loop in a circular economy and reinforcing sustainable construction practices.

Integrating Green Materials and Eco-friendly Maintenance

Projects must focus on integrating galvanized steel with other green materials like high-performance insulation and low-VOC (Volatile Organic Compound) interior finishes to maximize overall energy efficiency and indoor air quality.

For ongoing maintenance, the use of eco-friendly methods and non-toxic products is essential. These include:

- Biodegradable Cleaners: plant-based or enzyme-based detergents.

- Zero-VOC Coatings: water-based interior paints and sealants.

- Dry-Cleaning Techniques: methods like HEPA-filtered vacuums and microfiber cloths.

- Integrated Pest Management (IPM): barrier or traps to manage pests instead of chemical pesticides.

This ensures the entire structure, from the durable steel frame to its operational upkeep, maintains a healthy and low-impact profile.

Key Takeaway

True sustainability comes from thinking beyond the immediate build. By embedding galvanized steel into sustainable construction practices, developers gain a material that supports long-term efficiency, recyclability, and reduced environmental impact.

For products that stand the test of time and support your project’s sustainability goals, contact us today to access high-quality galvanized steel designed for resilient and eco-conscious construction.