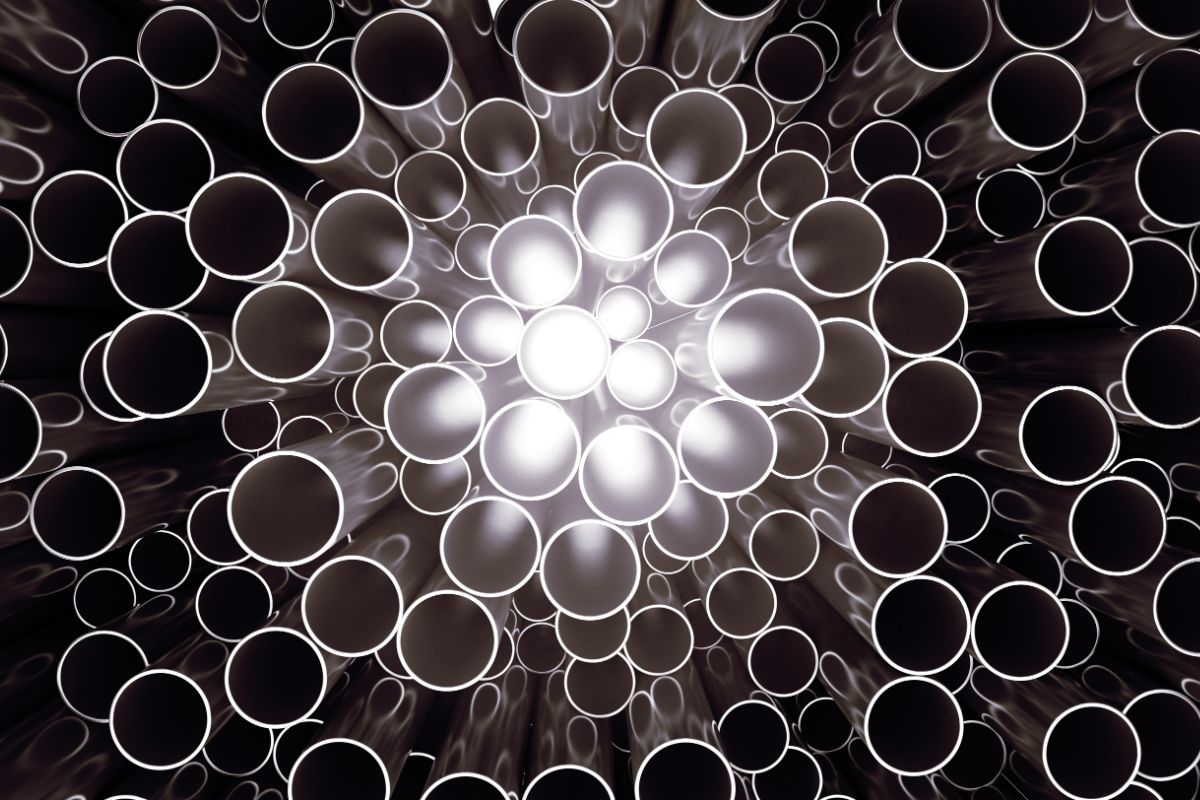

Making Black Iron Pipes: The Manufacturing Processes of Seamless Steel Pipes

Overview

- Black iron pipes are highly reliable for structural engineering. This is due to their chemical composition and meticulous manufacturing processes.

- Seamless steel pipes are produced without welds, resulting in a smooth, solid surface.

- Their manufacturing process involves methods such as hot rolling, cold drawing, and extrusion, each ensuring the pipe’s durability and precision.

- All the methods use heat initially to shape the steel, but cold drawing and extrusion involve additional steps compared to heat-rolling.

Black iron pipes are known for their reliability in various structural engineering projects. Their high-endurance qualities are a testament to their chemical composition and manufacturing process. As seamless steel pipes, they are made with different methods to ensure their integrity for all applications.

In this article, we explore the manufacturing process of seamless steel pipes, helping us make informed decisions when purchasing them for our projects.

What is a Seamless Steel Pipe?

A seamless steel pipe is characterized by its absence of welds, distinguishing it from pipes manufactured through welding processes. Typically crafted from whole-round steel, it undergoes a specialized manufacturing process to achieve its seamless construction.

By eschewing weld fabrication, seamless steel pipes boast a smooth and uninterrupted surface, offering numerous advantages across diverse industries, such as:

- Transportation of gas, oil, and other fluids or chemicals.

- Construction of infrastructure such as bridges and structural builds.

- Manufacturing materials for automotive parts like exhaust systems.

- Transmission and distribution of water supply.

These pipes are often made from carbon, stainless, or metal steel, making them durable and reliable for any project. These characteristics are heightened by corrosion-resistant properties—ensuring the longevity of your construction.

Processes in the Manufacturing of Seamless Steel Pipes

The production of seamless steel pipes is divided into many methods. Each technique is done with highly developed equipment. Investing in these machines is important in creating quality pipes.

Hot Rolling

High temperatures make even the strongest materials malleable. It is the same with molding steel materials into seamless pipes.

The pipes first begin as a steel billet. A billet is a semi-finished product. It is made by coasting molten steel into rectangular or square shapes. When it is cool, it solidifies and poses as a material suitable for further processes.

In creating seamless steel pipes, the billet is preheated in a furnace. Then, it is rolled through a piercing rod to create a hollow tube. Meanwhile, for the rolling process, it is adjusted to meet the right specifications, including the diameter and wall thickness of the pipes.

Cold Drawing

The cold drawing process does not avoid the need for high temperatures. Heating the billet is still necessary to form the material. After the use of hot temperatures, it undergoes a piercing process. This process requires a piercing rod to create a hole in the billet center. Then, it roughly takes the shape of pipes.

After that phase, it is elongated, reducing its diameter and increasing its length. A series of rolling operations is involved to refine its shape. It is then pulled through a die and plugged in cold.

Cold drawing is the main process wherein the heated billet is stretched to its right specifications. Room temperature is often required to perform this process. Then it moves to the annealing process. This is where the tubes are relieved of their stress from production.

Extrusion Method

The extrusion method has two main stages: the heating and the extrusion. In the first phase, the billet is heated in a furnace. This makes it more malleable to form our pipe shape. A piercing machine is also needed, which helps in making several holes in the material to make it more manageable.

The next method is the closed extrusion cylinder. It applies pressure to form the metal material into the desired details.

The main factors in this specific method are the direction of extrusion and the metal lever. It creates forward and backward extrusion. This refers to the direction of force and the metal flow. The former is when the two factors follow the same direction while the latter is the opposite.

Key Takeaway

The manufacturing processes of seamless steel pipes are the foundation of black iron pipes. Each method is a series of meticulous steps that ensure the pipes’ highest quality. Understanding the processes is important. It is an opportunity to learn the engineering excellence of making reliable construction materials.

In the continuous advancements in manufacturing steel materials, it is important to get your black iron pipes from a trusted supplier—Supreme Steel Pipe Corp. We are a group of experts that offer products and services on this versatile material. As demands for durable materials steadily grow, our team is at the forefront of adapting techniques to ensure the strength of our piping solutions. So, in your journey of finding high-performing black iron pipes, do not hesitate to contact us at SSPC today!