How Long Will My Galvanized Pipes Last?

Overview

- Galvanized steel is a robust choice for construction, plumbing, and outdoor applications, known for its ability to endure harsh conditions.

- The protective zinc coating prevents rust and corrosion, making it a durable and reliable material used across various industries.

- Galvanized pipes typically last around 40-50 years, influenced by factors such as environmental conditions and the type of galvanization.

- Careful consideration of usage and regular maintenance is essential to maximize the lifespan, as exposure to severe weather and chemicals can accelerate wear and tear.

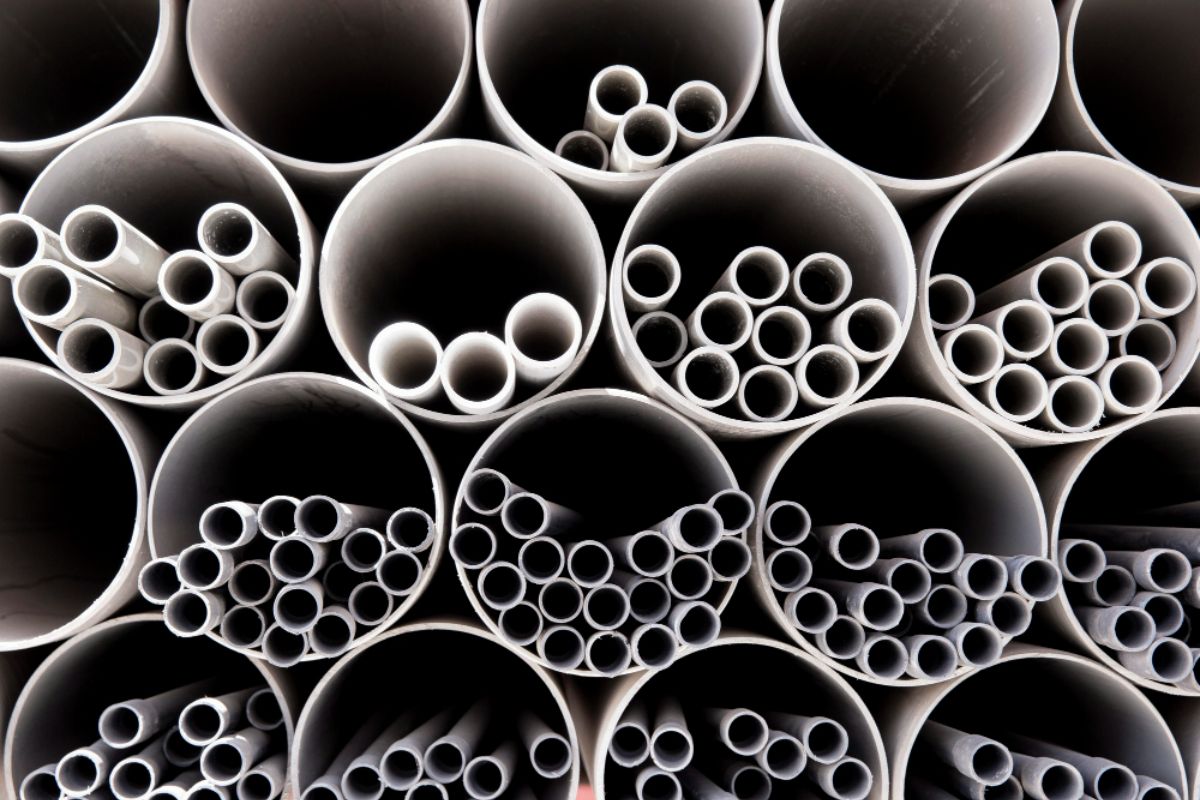

Galvanized steel, with its remarkable ability to endure harsh elements, stands as a vital choice for construction, plumbing, and outdoor applications. But what about its longevity? How long can galvanized steel endure the test of time, and what factors contribute to its remarkable resilience?

In this article, we aim to answer the question: how long will galvanized pipes last? To answer this, we will take a look at its different types to help you make informed decisions in selecting the right material for your needs.

What is Galvanized Steel?

Galvanized steel is a special kind of metal that has been coated with a protective layer of zinc. This coating helps keep the steel from getting rusty when exposed to the weather or tough conditions. This has made it popular for its durability and strength, making it a top choice across various industries where resistance to rust and corrosion is important. This includes building structures, vehicle manufacturing, and other industrial applications.

Since it doesn’t need a lot of maintenance, it is a more cost-effective option in the long run. This makes it a tough and reliable material that can handle all kinds of challenges in different industries.

How Long Do Galvanized Pipes Last?

Typically, galvanized pipes can endure for approximately 40-50 years. The lifespan of this material is influenced by various factors, including the environment, usage, and the type of galvanization.

However, you should take note that the protective zinc coating may wear off sooner in more challenging environments, potentially leading to corrosion. That is why it’s important to carefully consider the specific conditions in which the galvanized steel will be used, like exposure to severe weather, chemicals, and high humidity can speed up the wear and tear of the zinc coating.

Regular inspections and maintenance are also crucial to spot and fix any issues before they cause damage to the material.

What Are the Most Common Types of Galvanized Steel?

Whether you’re new to galvanized steel or looking to expand your knowledge and understand the most common types of galvanized steel, we will help you gain valuable insights into the world of coated steel products and make a better choice for your project:

Hot-Dipped Galvanized

Hot-dipped galvanized steel is coated with a long-lasting, extremely corrosion-resistant layer by submerging it in molten zinc. This procedure ensures a strong and long-lasting solution by preventing rust and corrosion, making it perfect for outdoor, structural, and marine applications.

The steel is first cleaned and then submerged in a 450°C (840°F) bath of molten zinc. This cooled zinc creates a thick, securely bonded layer that serves as a physical barrier to prevent corrosion after the steel is removed.

Its dependable ability against corrosion makes it the preferred choice for outdoor construction and maritime situations because of its durable and dependable protective covering. To those looking for cost-effective yet durable materials, you can opt for hot-dipped galvanized pipes because of their capacity to endure adverse conditions without losing integrity.

Electroplate Galvanized

Through an electrochemical process, electroplated galvanized steel applies a thinner zinc layer to the steel surface. While it effectively resists corrosion, it may not match the durability of hot-dipped galvanized steel in challenging environments.

Commonly used for indoor purposes and weight-sensitive projects, the electroplating process involves immersing the steel in an electrolyte solution with dissolved zinc ions. Upon the application of an electric current, these ions form a uniform protective coating, guarding against rust and corrosion.

Although not as robust in extreme conditions, its lighter weight and thinner coating make it suitable for specific applications where these attributes are advantageous. Industries and projects emphasizing precise weight management and corrosion protection in controlled indoor environments often find electroplated galvanized steel a practical and efficient choice.

Key Takeaway

Galvanized steel is a versatile and reliable material with the potential for a long service life when used and maintained correctly. So, if you’re still wondering how long will galvanized pipes last, you simply have to choose the right type of steel for your project’s requirements and, most of all, a partner that will help you ensure the extended lifespan of your galvanized steel.

By choosing Supreme Pipe, you’re not just selecting a material – you’re investing in longevity. Explore the enhanced durability of our aluminum solutions and elevate your projects beyond the lifespan of traditional galvanized pipes.

Make the smart choice for lasting impact. Contact us today for a consultation and discover the strength of Supreme Pipe in ensuring your structures stand the test of time.